User:Gjacuzzi

Rough Schedule

11/03 - order parts, finalize design, and create housing template

11/10 - finalize housing template, laser cut housing, begin assembly

11/17 - finalize assembly and begin programming

11/24 - finalize programming

12/1 - solve any remaining issues and take care of fine tunings

12/2 - make and practice presentation

12/3 - final presentation

12/4 - documentation

Sketches

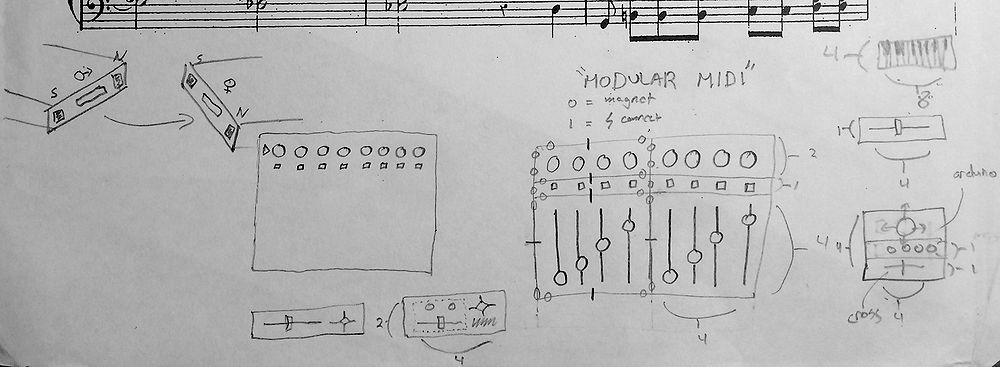

Original off-the-cuff concept sketches for a modular midi controller, note magnetic connections

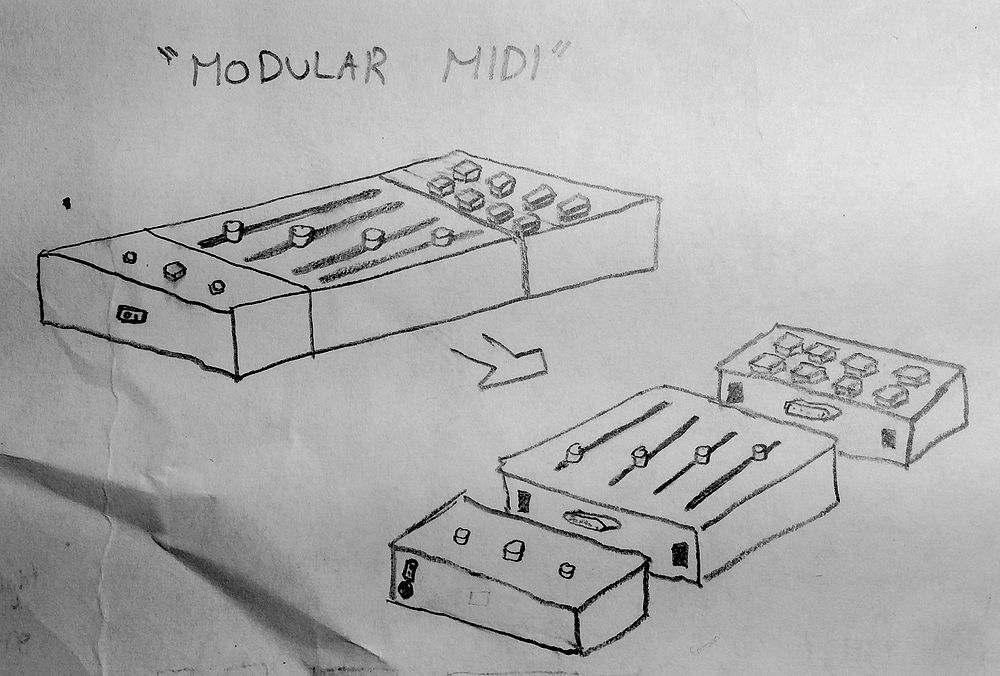

Fine-tuned 3d sketch of the modular midi concept

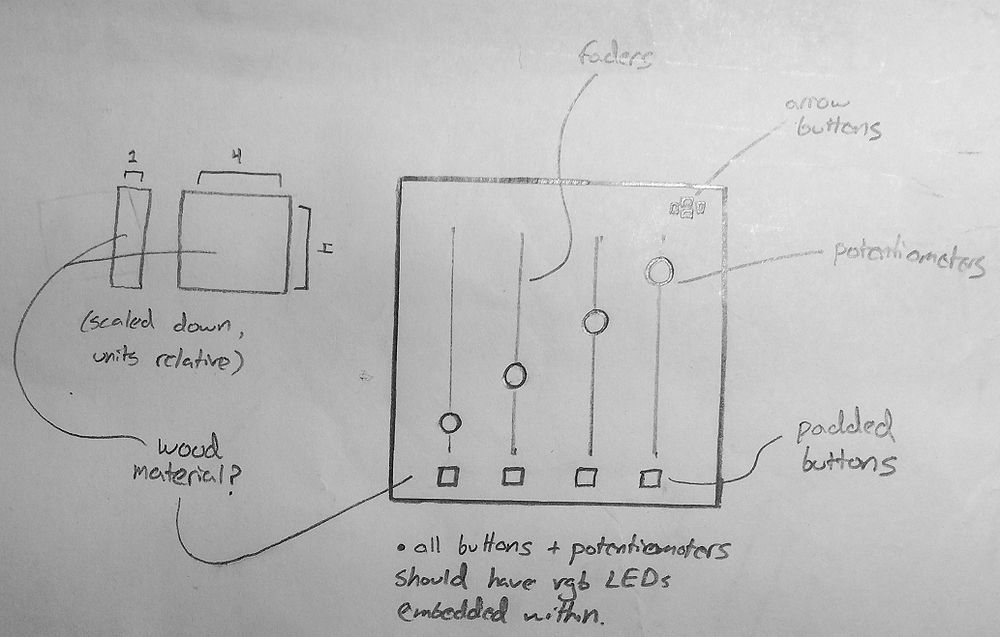

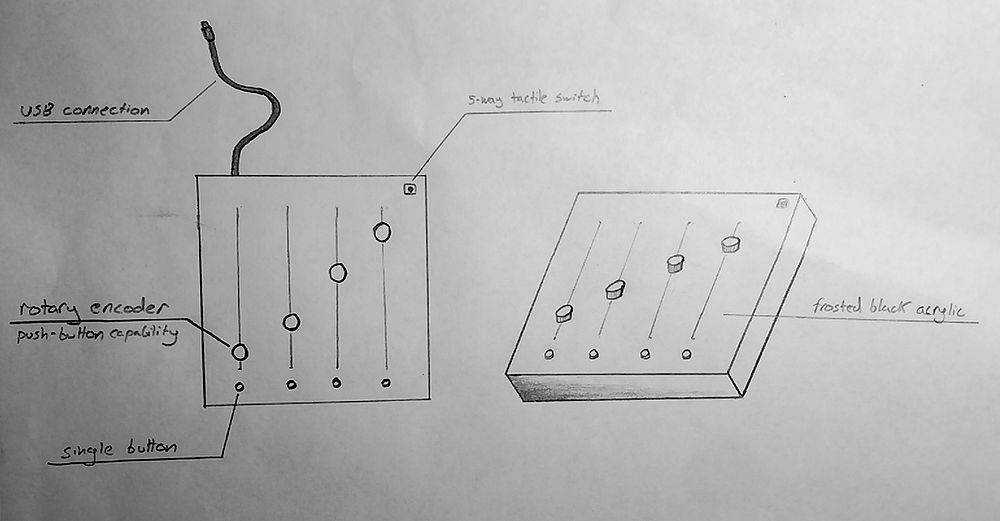

Abandoning modular midi for the sake of time and complexity, focusing on a single component

Current concept sketches for multi-functional midi controller

Research + Info

Examples of other work

- Yamaha / Toshio Iwai -- Tenori-on (http://www.global.yamaha.com/tenori-on/)

- Jazzmutant Lemur (http://www.youtube.com/watch?v=X_BMnwIbWJw)

- Dillafiler (https://ccrma.stanford.edu/wiki/Dillafier)

- Ableton - Akai APC40 (http://www.akaipro.com/product/apc40)

- Icon Digital USA - iControls - Mini USB MIDI Controller (https://www.icondigitalusa.com/content/icontrols-mini-usb-midi-controller)

MVP

The Plan

Unlimited Time + Resources Vision

Elevator Pitch

Materials Needed

* motors (6, one for each disk)

* MOSFETs (6) http://www.jameco.com/webapp/wcs/stores/servlet/Product_10001_10001_669951_-1

* tubes/air hose (24)

* solenoid valves (24):

* 7psi model (might need more): http://www.jameco.com/webapp/wcs/stores/servlet/Product_10001_10001_169835_-1

* air directional control valves: http://www.mcmaster.com/#air-directional-control-valves/=p6xufn

* arduino (1)

* power source (1?)

http://www.12vadapters.com/adapter/power-supply/12v/10-amp-10a.html

* keys/piano/organ interface (faders + buttons + enclosure)

* disks (12)

* enclosures for the disks (6)

* horns? (6)

* also check out air (pneumatic) controls for air rifles, potato canons, pipe organs, etc. http://www.youtube.com/watch?v=DG6own141z0 shows how to make a homemade check valve with pvc connectors and a bouncy ball.

Next Steps. The next steps are to build a 5-fader, 4-button, 1-motor model, where 4 faders are devoted to air hoses over the individual rings of 1 disk (different pitches) and control the air pressure of each hose, and 1 fader is dedicated to the spin of the motor. The 4 faders could possibly control ball valves to partially open/close the air hoses as opposed to flow, which we do not have a good grasp of how to control (cheaply; a regulator might work). The buttons could also serve as the valve control, or could power on/off the air supply.