CCRMA Documentation links: index contents overview rooms account staff about

(contents of this file: links to each

section)

Laser Cutter – Garage

Room contents

- Epilog

Helix 40-watt, s/n 8040-14150332418R

- Work area is 24” x 18”

- Small red vacuum mounted just above for quick manual cleanup

- Desktop cart

- video, keyboard, mouse

- Dell OptiPlex 7080 (USB port)

- LaserCutter USB flash drive for transfering your projects to the

desktop

- Manual safety gauge (small “V” shape metal piece)

- Air compressor (small grey unit): Gast DOA-P709-AA, feeding clean

air into the laser cutter to power the internal exhaust system.

- Quatro iSeries filtration unit, taking bad stuff out of the laser

cutter’s output exhaust

- Pedastal Fan, for blowing exhaust (post-filtration) out the

door

- Material rack on bottom rack

- Fire extinguisher

Materials it can cut/engrave

- Acrylic

- Acrylic comes with disposable film on both sides. Dispose the

protective adhesive paper from the back and place the front protective

layer side down on the rack (acrylic scratches easily).

- Optionally, add a layer of masking tape to prevent scorching stains.

Press it flat and make sure there are no bubbles.

- Wood

- Like acrylic, you can optionally add masking tape.

- Avoid construction grade material with lots of glue/particulates,

e.g., plywood or especially medium density fiberboard (MDF). It’s not as

efficient for the laser and can impede the cleaning job (extra dust can

catch fire).

- Engravable metal (no vector cutting on metal)

- Glass

- Cork

- Leather

- Paper

- Full

list here

Consult the laser approved materials list and familiarize yourself

with the safety protocol. Note that some materials can be engraved but

not cut. Additionally, there is a list of suggested speed/power settings

per material next to the desktop in the laser cutter room, as well as in

the manual (Appendix B: Material Settings). Using improper settings

may lead to a fire hazard, so always refer to the recommendations.

Software

For sending your design to the laser cutter, “this model of machine

will only work on a windows operating system.” Epilog recommends Adobe

Illustrator or Corel Draw. (Also they have a workflow with Inkscape, but

it requires special drivers (zip

file from Epilog for 64 bit versions of windows) and you have to

export to pdf and print the pdf from Adobe Acrobat.)

You don’t need to worry about that if you just use the CCRMA

laser cutter Windows machine:

- Account is “laser cutter” and has no login

- Corel Draw is the software that “talks” to the Helix. As far as

Corel Draw is concerned, the Helix is just another printer.

- Get your files onto this machine via USB stick and/or Internet

- Open your design file(s) in Corel Draw

- Corel Draw can read Adobe Illustrator files. It even gets the

“layers” right.

Creating a design

- Create a new document and specify your material’s dimensions in

inches in the initial set-up window.

- For a vector cutting design, you must use a “hairline” line

thickness, or 0.001 inches, for the laser cutter to interpret it as a

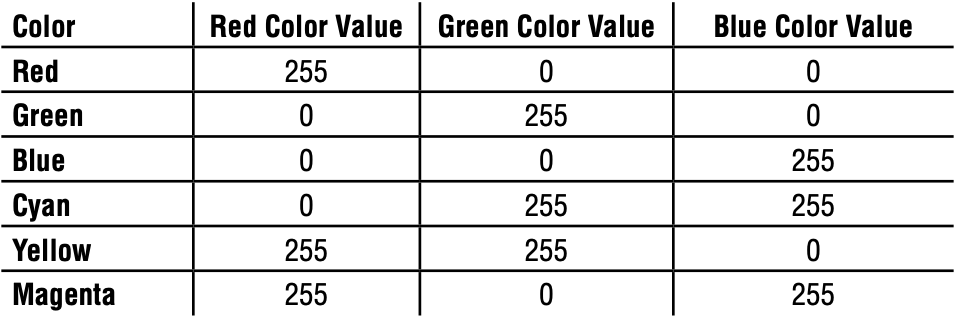

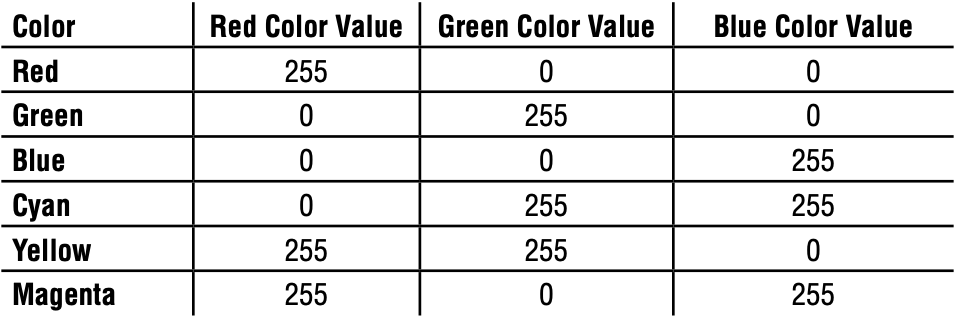

vector. Use only RGB value combinations of 0 or 255 such as black (0, 0,

0), or refer to the chart below. Anything else will be ignored.

- Line thickness doesn’t apply to raster engraving – any thickness or

continuous shade/gradient is fine. However, appropriate RGB colors still

matter. Below is a chart of the RGB values from the manual:

- If your design includes both raster engraving and vector cutting,

separate those portions in different layers.

- Tip: use different basic RGB colors to indicate a raster engraving

or vector cutting job (e.g., black (0, 0, 0) for vector and red (255, 0,

0) for raster).

- The Helix is very precise but material placement is not, so leave

yourself a margin of error in your template.

- Tip: If you’re working with acrylic, horizontally mirror your design

(left to right) so the laser will be engraving the backside.

Safety protocol

All general shop rules apply to using the laser cutter (e.g., always

wear shop glasses, only closed-toe shoes, tie long hair back). Here are

some important fire safety tips to remember:

- Never leave the Helix unattended when cutting material!

- Some materials can literally burst into flames, even if commonly

used.

- Always make sure there is proper ventilation (iSeries and standing

fan).

- If a small fire is sparked, open the lid immediately (this will stop

the job).

- Blow it out if it continues burning.

- If it’s larger than that, put it out with the fire extinguisher in

the main garage room.

- If it’s unmanageably huge, evacuate and call 911.

Setting up the Helix

- Turn on the power switch on the lower left next to the power

cable.

- Open the glass lid and place your material on the honeycomb

rack.

- Press “X/Y Off” then “Go” to off to disable motors so you can move

the laser by hand; display will flash “X/Y Disabled”. Press the

“Pointer” button to turn on a little red dot, then manually position the

laser head at the material’s “origin” (top left corner).

- If your material is not flat, you must manually focus the laser on

your material (otherwise, it’s your choice, though auto-focus poses

potential risks to the machine). Make sure the engraving area is still

relatively flat.

- To manually focus: after completing step three, put the manual focus

gauge on the carriage and press the “Focus” button. Then, use the up or

down buttons to move the table until the gauge touches a midpoint

between the lowest and highest parts of your material. Then, press

“Reset”. The carriage should return to the upper left corner and your

focus height will be saved.

- Press “Set Home” and “Go”, then press “Pointer” to turn it off.

Close the glass lid.

- Press “Reset”. The display says “Job: “ which indicates the default

state of the Helix waiting for a job. The Helix is now ready to receive

instructions from Corel Draw.

- Turn on the air compressor (small grey metal device under the Helix)

and press the red power button on the iSeries filtration unit (large

white box with tube). Both must be turned on while laser cutting.

- For acrylic projects, additionally turn on the standing fan next to

the door.

- You have a choice of opening the door leading outside (on your right

when facing the Helix) during your print. Opening it may give you

additional ventilation, but the extra heat and dust can affect the

laser’s performance.

Printing Your Design

to the Laser Cutter

- Confirm the “paper size” as 24x18 inches (or smaller)

- Corel Draw: Layout > Page Size… >

- Illustrator…? XXX

- If your project involves both raster engraving and vector cutting,

raster first. Hide the vector layer (or any other raster layers if doing

multiple intensity rasters) by clicking the eye icon next to the

layers.

- Press “Control + P” to print. Choose “Epilog Engraver WinX64” as the

printer.

- Click the settings icon next to the selected printer (looks like a

gear) to bring up Epilog’s settings window.

- In the Epilog window (which has distinctive graphics), start by

selecting “Raster” or “Vector” as the job type (depending on your job).

Do not select “Combined.” Then, set your resolution in dots per inch

(DPI); between 300-600 DPI is standard for most purposes (higher = more

detailed).

- Refer to the wooden chart behind the desktop and/or the manual’s

suggestions for laser speed/power/frequency per your material. For

example, the chart suggests 60%/100% for a 600 DPI raster job on wood.

Input your settings.

- Make sure auto-focus is checked and the piece size matches your

material’s dimensions. (Epilog’s settings seem to revert to 8.5 x 11

even if you already told Corel Draw that your “piece” is 24 x 18

inches.)

- Do not check auto-focus if you manually focused.

- Press “OK” when done with the Epilog window, then “Apply” to save

your settings.

- Double check that your file’s media size matches the material’s

dimensions (use inches).

- Now click the “print” button. This will send the job to the

Helix.

- Press “Go” on the Helix to start laser cutting.

- If your project involves both vector cutting and raster engraving,

repeat steps 7-15 for each layer and change the Epilog window settings

accordingly.

- If you need to stop the job at any time (e.g., if something catches

fire), the quickest way is to lift the glass lid. You can also press

“Stop” on the Helix, but this is slightly slower.

- When your job is done, press the trash icon on the Helix.

Cleaning the laser cutter

- General cleaning

- Vacuum the crumb tray (inside the machine, see below) as often as

possible.

- Move the computer out of the way, then open the front door. Turn on

the air compressor to remove dust buildup.

- Use a q-tip soaked in 99% isopropyl alcohol to clean the auto-focus

plunger tip.

- Optics (mirrors and lenses)

- About once a week (during heavy usage) or if dust builds up, the

optics may need cleaning.

- First, press “X/Y” and set “Go” to off to disable motors and move

the laser by hand.

- Use a q-tip soaked with the optics cleaning solution to lightly swab

the lens, taking care not to rub or push. Hold the q-tip loosely and

spin the head to remove impurities.

- If the optics cleaning solution runs out, use the 99% isopropyl

alcohol in the cleaning supply box instead.

- Crumb tray

- If small pieces fall through the honeycomb while cutting, open the

laser’s front access door to slide out the crumb tray and clean debris.

- This becomes a fire hazard if not regularly checked and

cleaned!

- Advanced (for staff performing maintenance)

- The honeycomb grid can be cleaned by immersing

in a diluted degreaser. Otherwise, it can be replaced through

Epilog.

- Cleaning materials

- Drain pan large enough to fit 24”x18” grid

- Zep Industrial Purple Degreaser

- Hot water

- Bucket for hot water

- Hazardous waste container (for dumping all Zep contaminated water)

- Virtually any container that can be sealed shut and won’t leak if

you turn it upside down

- Pipe cleaner (optional)

- Rubber gloves

- Safety goggles

- Use 1 part Zep Industrial Purple Degreaser to 10 parts hot water (or

1:5 if the grid is very dirty) to fill the drain pan. Submerge the grid

for no more than 1-2 minutes, dump the cleaning mixture out of the tray,

then rinse the grid with water in the tray. Optionally, use a pipe

cleaner to remove debris stuck in the honeycomb. Let the grid dry

completely before reattaching it to the laser. Finally, dispose of the

waste by submitting a Stanford hazardous waste

pickup request.

- Do not dispose of any Zep or Zep contaminated water in a sink or

storm drain. You must file a waste pickup request.

- Avoid sunlight and conduct the process in an area with good

ventilation (e.g., shaded outdoors).

- Avoid soaking for longer than 2 minutes or the grid can be damaged

(the coating may wear off).

- The Zep degreaser is very powerful. Wear safety goggles, a mask,

rubber gloves, closed-toe shoes, and cover exposed skin when using

it.

- Air intake comes from four holes in the machine’s rear – keep them

clean.

- Use a q-tip soaked in 99% isopropyl alcohol to clean along the

X-axis bearing rail. Gently move the X-axis belt out of the way to

access the rail, being careful not to tug at the belt.

- There is an extra X-axis belt in the cleaning supply box to replace

the old one.

- If any other maintenance issues come up, contact Matt.

This page of CCRMA documentation

last committed on Thu Sep 11 11:55:36 2025 -0700 by Matthew James Wright.

Stanford has a page for Digital Accessibility.